ABU 6500 CS Rocket Strip

Although this article is on the CS Rocket 01-04, it equally applies to other ABU 6500’s (although part numbers will vary). I am not an expert reel technician and this is not meant to be an egg sucking exercise for those who are already familiar with stripping down a reel. This has been done as a guide on to how I strip and clean a reel in the hope that it may help those who are not used to taking these apart. The one being used here is my old and trusted 6500 CS Rocket (01-04 model) that I’ve had for years and has never let me down even after all the abuse it’s had.

Hyperlinked part names link to their respective part numbers in the Parts List at the end of the end of the page. Parts and their part numbers shown here pertain to this particular model, so may differ from other reels depending on model and year.

Print This Page Beware, image heavy!

Print This Page Beware, image heavy!

A list of things I use:

- Clean lint free cloths

- Suitable solvent (lighter fluid is good)

- Small flat blade screwdriver

- Small Phillips screwdriver

- Spanner to fit handle nut

- Reel oil

- Reel grease

- Small paintbrush

- Toothbrush

I find that having everything organised first saves time and makes it easier to find the bits that drop off (they will). I sometimes use an old white hand towel for laying the various parts on but for these photos, I didn’t have it, as it was having fish guts removed in the wash.

The first thing to do is give the reel a good rinse and scrub with a toothbrush under running water to remove excess salt and crap and then dry. As you can see, I didn’t. Fig1

Fig. 1

Remove the small screw and retaining tab around the handle nut . Undo the the handle nut and remove the handle. You may have to remove the small circlip on the top of the shaft to get the handle off but on mine, the handle will come off over it. Beware as this is a slippery little sucker and will fly off, either never to be found again or to be found when the nice doctor digs it of your eye. Next, remove the small handle spring washer and unwind the star drag adjuster until it comes off the shaft. Lay the items out in the order you remove them, to make it easier when re-assembling. Fig2.

Fig. 2

Undo the three knurled captive screws on the right hand side plate and remove it. The spool spindle will come out attached to the side plate. Slide the spool out of the cage and put to one side for the moment. To prevent losing the small brake blocks and leave you like a dribbling, muttering fool on your hands and knees, slide them off their pins and put in a safe place. Undo the knurled tension cap on the end plate and remove the spindle retaining clip and withdraw the spool spindle Fig 3.

Fig. 3

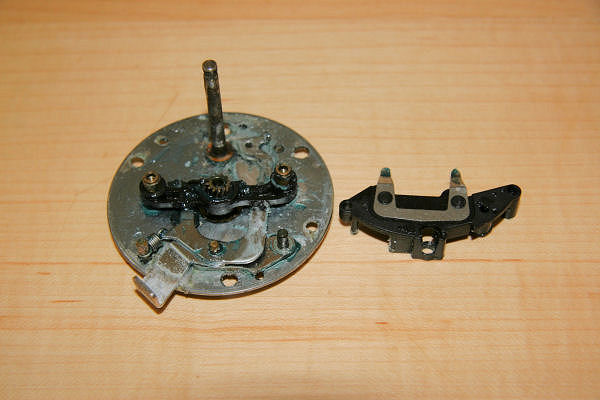

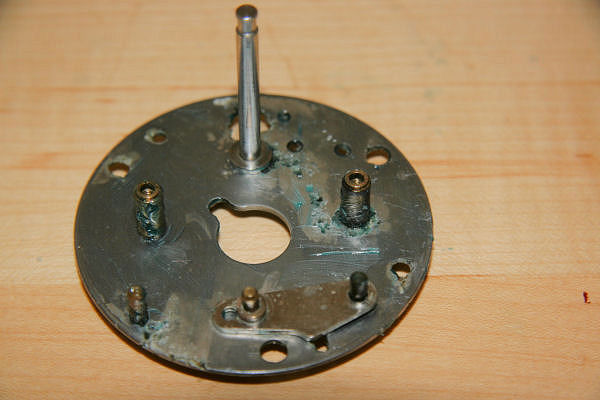

Undo the two smaller side plate screws to release the side plate from the brake plate and the internals. Fig 4.

Fig. 4

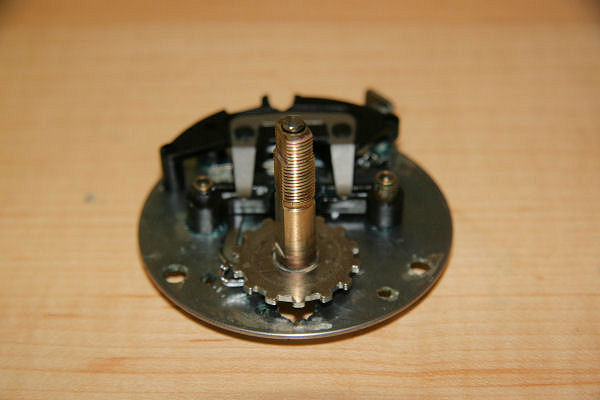

If not already done, remove the small circlip (heed the warning) at the top of the drive shaft and pull the shaft and drag assembly off the spindle. Fig 5.

Fig. 5

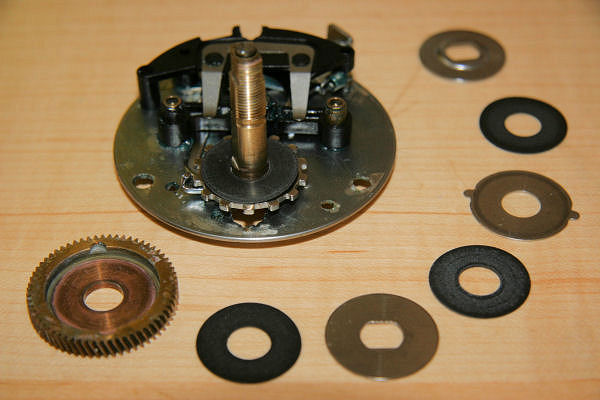

Now remove the main gear and drag system components from the gear shaft and lay them out in the order they came off. Look after them, as they are notoriously difficult and messy to retrieve from your pet. The drag components consist of a mixture of stainless steel washers and fibre washers Fig 6.

Fig. 6

These components may well need a good clean to remove any oil or grease. The easiest way is to get a shallow container, put the components in and cover with lighter fluid (taking all necessary safety precautions of course) and agitate gently them gently for a short while before taking them out and laying on absorbent paper to dry thoroughly. Fig 7.

Fig. 7

Turning attention to the rest of the innards, remove the spool release pressure plate Fig 8.

Fig. 8

…and the pinion gear yoke Fig 9.

Fig. 9

Remove pinion gear from the front of the yoke with gentle finger pressure (Remembering which way it goes back – stubby end with the slot faces down) Fig 10.

Fig. 10

Now lift the clutch release arm off its pin after disconnecting from the small spring Fig 11.

Fig. 11

Remove Clutch release push button Fig 12.

Fig. 12

…and the connector arm Fig 13.

Fig. 13

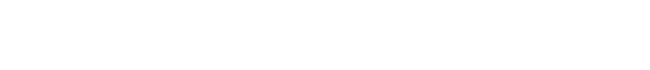

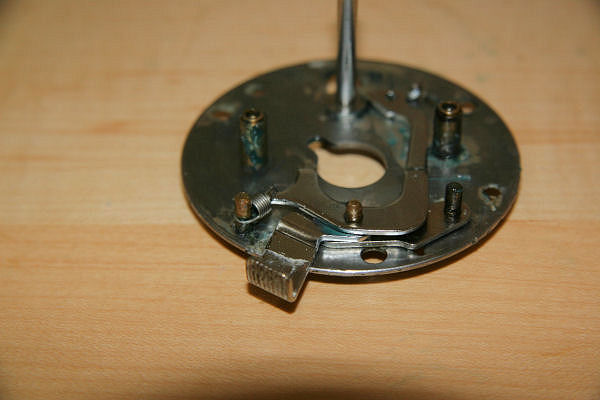

Clean all parts thoroughly with solvent, dry and re-grease with reel grease. Also re-pack the pinion yoke with grease before popping the pinion gear back in (the right way up). Figs 14, 15 and 16

Fig. 14

Fig. 15

Fig. 16

Now re-assemble the clutch release system. Pop the connector arm onto the post as shown Fig 17.

Fig. 17

…and the clutch release push button Fig 18.

Fig. 18

… followed by the clutch release arm, remembering to re-attach the small spring Fig 19.

Fig. 19

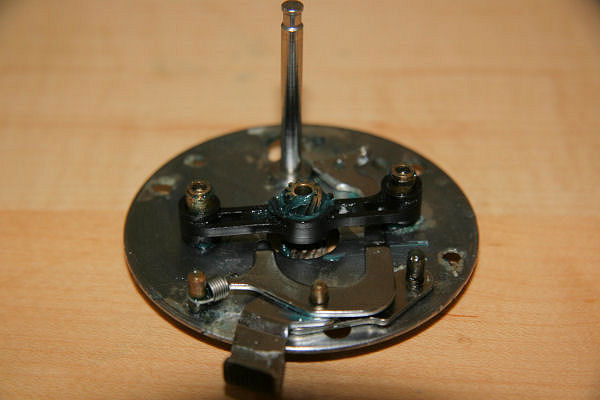

Push the pinion yoke – with the pinion gear already fitted in – onto the two posts Fig 20.

Fig. 20

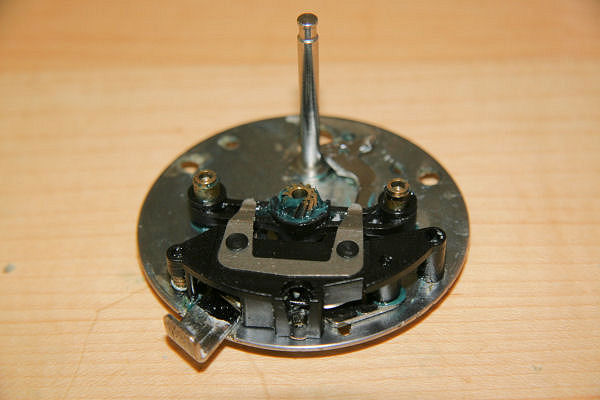

Now push the spool release pressure plate down onto the posts as shown Fig 21.

Fig.21

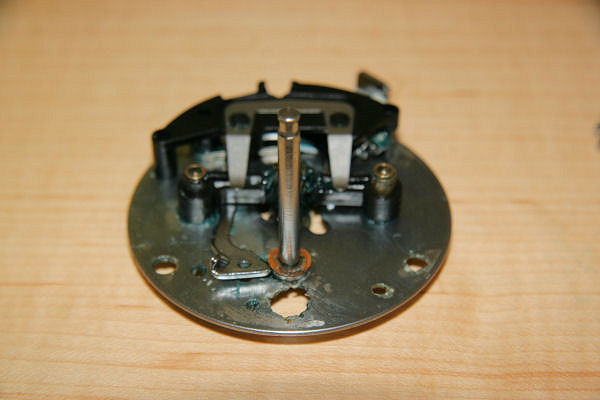

To re-assemble the main gear and drag system. Lightly grease the drive shaft spindle before sliding the small copper drive shaft shim onto it, followed by the drive shaft Figs 22 and 23.

Fig. 22

Fig. 23

Slide the smaller of the fibre washers onto the drive shaft, followed by the main gear (make sure it engages with the pinion gear) and drag washers in the sequence shown – fibre, stainless steel, fibre, stainless steel tabbed, fibre, stainless steel domed – ensuring that they do not get contaminated with grease or oil. Figs 24 and 25

Fig. 24

Fig. 25

Now slide the IAR bearing bush over the shaft Fig 26.

Fig. 26

Before refitting the side plate onto the backing plate, grease the instant anti reverse (IAR) bearing which is housed in the aperture that slides over the shaft. Once done, slide the side plate over the shaft and secure with the two small screws before sliding the drag sprung washers over the drive shaft. Figs 27 and 28

Fig. 27

Fig. 28

Having finished assembling the right (drive) side, put it to one side and go on to the next part.

Unless you are removing the spool bearings for cleaning or replacement, there’s no need to do much here apart from a light clean to remove any debris and to add a drop of oil to each bearing. On the drive side, the bearing is obvious, sitting under the brake block carrier. Fig 29

**As an aside it should be mentioned that when purchasing the spool, it comes as a complete unit comprising of the spool, bearings, shim, ratchet/level wind drive cog, brake block carrier and circlip. You can still get the component parts separately should you need to**

Fig. 29

The opposite bearing sits under the white plastic ratchet cog which is easily (but gently) prised off with a flat blade screwdriver. Fig 30

Fig. 30

Having done the spool, put it one side with the completed right end plate. Go the other side and remove the three retaining screws and take the left side plate off Fig 31

Fig. 31

To remove the level wind, first unclip one end of the small retaining plate that holds the cog at the end of the level wind worm gear Fig 32

Fig. 32

On the level wind bar, undo the screw and remove the pawl cap. The pawl itself may come out with the cap but if not, gently prise it out with a small flat blade screwdriver. Fig 33

Fig. 33

Now completely remove the worm gear, the small retaining plate, the level wind bar and the level wind guide Fig 34.

Fig. 34

Give all parts a thorough clean before lightly oiling and re-assembling using the reverse order of removal and making sure that the pawl engages fully with the worm gear. Figs 35-38

Fig. 35

Fig. 36

Fig. 37

Fig. 38

The end plate itself requires little doing to it apart from good clean, re-grease of the ratchet system, a drop of oil in the tension end cap and drops of oil in the brass bullet that holds that end of the reel spindle and the spindle of the idler gear (white plastic cog) Figs 39 and 40 before being re-attached with the three small screws.

Fig. 39

Fig. 40

The spool and spindle can now be re-assembled. With the reel cage laying on its left side, drop the spool into place with the small plastic cog end going in first and being careful not to lose the fibre brake blocks. Fig 41

Fig. 41

After lightly oiling, slide the spool spindle into the spool with the brass spacer at the right hand end. Fig 42

Fig. 42

Replace the right (drive side) end plate ensuring that the spool spindle locates properly through the brass pinion gear and protrudes through the end plate. Make sure that the end plate fits correctly before securing it with the knurled captive screws. Fig 43

Fig. 43

Replace the black plastic spindle clip and screw back the tension cap Fig 44 and 45

Fig. 44

Fig. 45

Replace the star drag onto the drive shaft, taking care not to cross thread it and wind it down to the bottom of the shaft Fig 46

Fig. 46

Replace the spring tab and the handle Figs 47 and 48

Fig. 47

Fig. 48

Replace the circlip before replacing the handle nut and tightening Fig 49.

Fig. 49

Now replace the retaining tab and secure it with the small screw Fig 50.

Fig. 50

And that’s it, all done. To make sure all is working ok with no problems, check that the spool disengages cleanly and re-engages when the spool is turned by the handle. Check that the drag system works smoothly with no snatchiness. Make sure that the spool spins smoothly with no excessive noise. Ensure that the level wind works correctly. In general, does the reel run like new? If any problems encountered, strip it down again and find the source of the problem, don’t leave it until you’re on the beach with the fish of a lifetime on the other end – because you can bet a pound to a pinch of crap that that’s when the reel will fail.

For all reel schematics and part numbers, take a look here

[stextbox id=”grey” caption=”Parts List” color=”000066″ bcolor=”000000″ bgcolor=”e3e1dd”]

Brake blocks: ABU Part no. 22565

Brake block carrier: ABU Part no. 22567

Brake plate: ABU Part no. 22820

Brass bullet: ABU Part no. 20639

Circlip: ABU Part no. 4490

Clutch release arm: ABU Part no. 22807

Clutch release push button: ABU Part no. 20671

Connector arm: ABU Part no. 20685

Drag sprung washers: ABU Part no. 5131

Drag washers – fibre: ABU Part no. 13169 and 20907

Drag washers – stainless steel : ABU Part nos. 20906, 20905 and 20960

Drive shaft: ABU Part no. 22079

Drive shaft shim: ABU Part no. 5189

Handle: ABU Part no. 20932

Handle nut: ABU Part no. 5327

Handle spring washer: ABU Part no. 5115

IAR bush (Instant Anti Reverse): ABU Part no. 22001

Left hand side plate: ABU Part no. 20840

Level wind bar: ABU Part no. 2496

Level wind guide: ABU Part no. 5174

Main gear: ABU Part no. 21200

Pawl: ABU Part no. 5176

Pawl cap: ABU Part no. 5177

Pinion gear: ABU Part no. 20848

Pinion gear yoke: ABU Part no. 20664

Idler gear: ABU Part no. 5152

Ratchet cog: ABU Part no. 19373

Ratchet system: ABU Part nos. 8744, 8904, 4467, 8745, 4464, 4465 and 3909

Retaining plate: ABU Part no. 5178

Retaining tab: ABU Part no. 20944

Right hand side plate: ABU Part no. 21291

Screw: ABU Part no. 301

Sideplate screws: ABU Part no. 304

Spindle retaining clip: ABU Part no. 20090

Spool: ABU Part no. 970450

Spool assembly: ABU Part no. 970450

Spool bearings: ABU Part no. 13472

Spool release pressure plate: ABU Part no. 22808

Spool spindle: ABU Part no. 802631

Star drag adjuster: ABU Part no. 20925

Tension cap – left hand: ABU Part no. 9597

Tension cap – right hand : ABU Part no. 10239

Worm gear: ABU Part no. 5205

[/stextbox]