Akios 656CSM strip

This article is on the Akios S-Line 656 SCM, which which I bought to replace my trusty old ABU 6500 CS Rocket that recently expired after many years of use and abuse. On first looks, the Akios is so similar to the rocket, that it might as well be just a newer version of it. In fact, it is so similar that there probably isn’t any need to do a separate write up on the strip down – but hey, what else can I do to fill the time when I can’t get out fishing?

As I’ve said before, I am not an expert reel technician and this is not meant to be an egg sucking exercise for those who are already familiar with stripping down a reel. This has been done as a guide on to how I strip and clean a reel in the hope that it may help those who are not used to taking these apart.

Hyperlinked part names link to their respective part numbers in the Parts List at the end of the end of the page. Parts and their part numbers shown here pertain to this particular model, so may differ from other reels depending on model and year. I have to say though, that the schematic and parts list is somewhat confusing, in that it often gives multiple part numbers for one part. In this article, I have put the part numbers as given, so if ordering any parts, please be careful and check that you are getting the correct piece.

Print This Post Beware, image heavy!

Print This Post Beware, image heavy!

A list of things I use:

- Clean lint free cloths

- Suitable solvent (lighter fluid is good)

- Small flat blade screwdriver

- Small Phillips screwdriver

- Spanner to fit handle nut

- Reel oil

- Reel grease

- Small paintbrush

- Toothbrush

I find that having everything organised first saves time and makes it easier to find the bits that drop off (they will). For this article, I used my trusty white towel – sometimes this is not available as it’s in the wash being cleaned of fish guts and old bait but in this instance was clean(ish).

The first thing to do is give the reel a good rinse and scrub with a toothbrush under running water to remove excess salt and crap and then dry. As you can see, this one didn’t need too much work as it’s virtually brand new. Fig1

Fig 1.

Undo the small screw and remove the retaining tab around the handle nut . Undo the the handle nut and then remove the small E-clip on the top of the shaft to get the handle off. Beware as this is a slippery little sucker and will fly off, either never to be found again or to be found when the nice doctor digs it of your eye. Remove the handle and the small handle spring washer (spacer) under it and then unwind the star drag adjuster until it comes off the shaft. Lay the items out in the order you remove them, to make it easier when re-assembling. Fig 2.

Fig 2

Undo the three knurled captive screws on the right hand side plate and remove it. The spool shaft (spindle) may come out attached to the side plate. Slide the spool out of the cage and put to one side for the moment. Fig 3.

Fig 3

To prevent losing the small brake blocks and leave you like a dribbling, muttering fool on your hands and knees, slide them off their pins and put in a safe place. Fig 4

Fig 4

Undo the knurled cast control cap on the end plate and remove the Shaft (spindle) retaining clip and withdraw the spool spindle Fig 5.

Fig 5

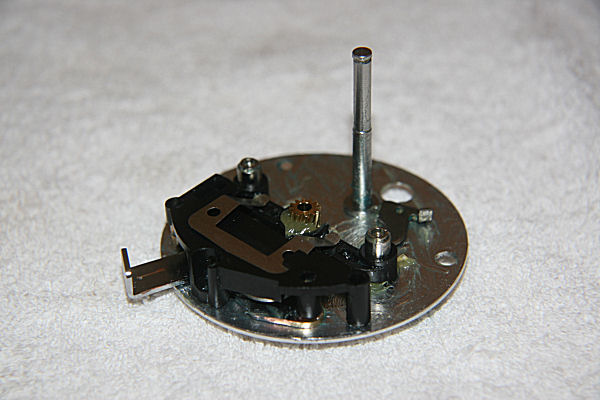

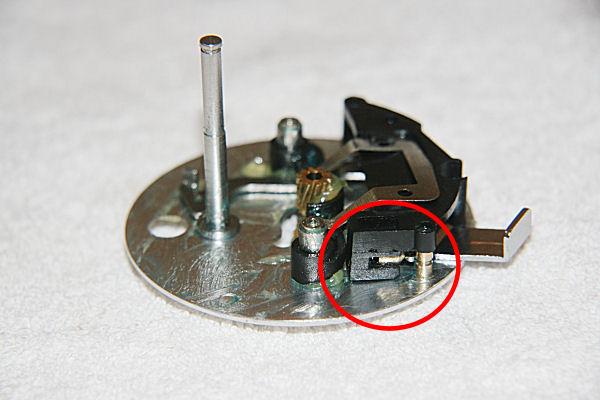

Undo the two smaller side plate screws to release the side plate from the brake plate and the internals. Be careful not to lose the two small plastic washers off the screws, as I reckon they’ll be harder to find than a straight answer from a politician. Pop out the bushing that sits under the knurled cast control cap that was removed in the previous step. You may well find that sitting in the hole left by the drive shaft, will be two spring washers, dig the critters out and put to one side for cleaning. Figs 6, 7, 8 & 9

Fig 6

Fig 7

Fig 8

Fig 9

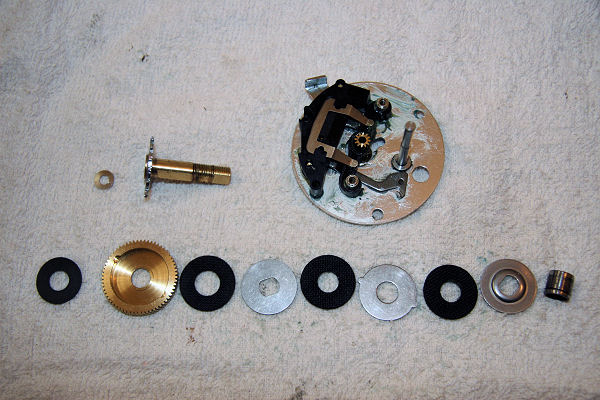

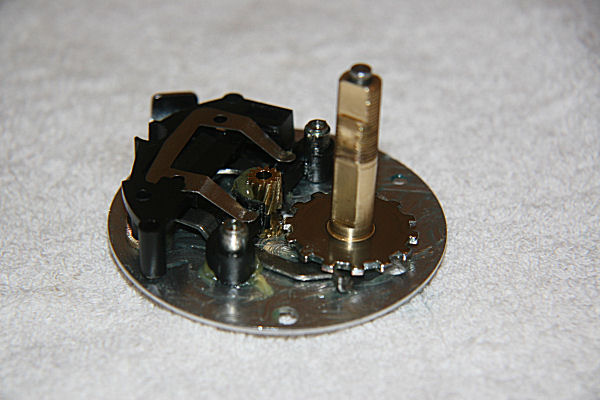

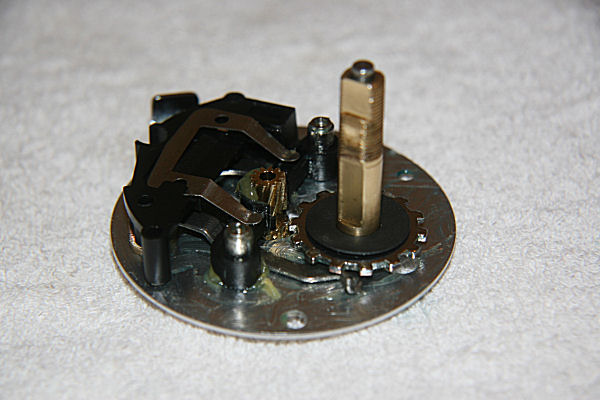

Take the brakeplate assembly and if not already done, remove the small E-clip (heed the warning) at the top of the drive shaft. The drag components, which consist of a mixture of stainless steel washers, fibre washers and other pieces need to be removed. Now you can do this in one of two ways: 1) Pull the shaft and drag assembly off its spindle and then take all the components off , or 2) as I have done here to show the order, take all the components off the shaft first and lay them out in the order they came off. Fig 10. The first method is probably easier but you run the risk of accidentally dropping all the pieces and then not knowing their order; plus they are notoriously difficult, messy and expensive to retrieve from your pet. So here is the order they come off going from right to left – One way bearing (Instant Anti Reverse),> Key washer (domed),> fibre drag washer,> ear washer,> fibre drag washer,> key washer (flat), fibre drag washer,> drive gear,> drive washer

Fig 10

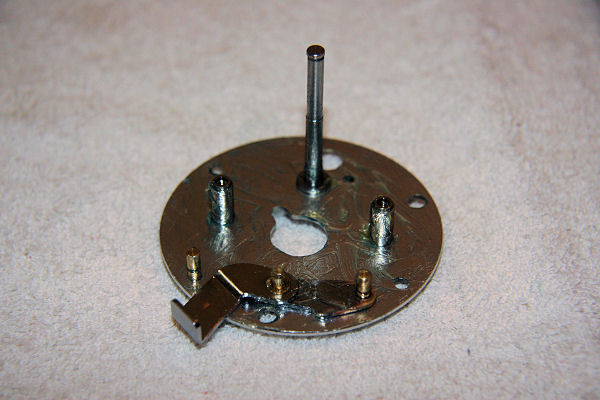

Now remove the drive shaft from the spindle. You will probably find the the release gear will come off attached to the Drive shaft. Now remove the final piece, the tiny spring washer. Fig 11 below, shows all the drive shaft and drag components laid out, in order from right to left with the drive shaft and spring washer above.

Fig 11

These components may well need a good clean to remove any oil or grease. The easiest way is to get a shallow container, put the components in and cover with lighter fluid (taking all necessary safety precautions of course) and agitate gently them gently for a short while before taking them out and laying on absorbent paper to dry thoroughly. Fig 12.

Fig 12

Turning attention to the rest of the innards, remove the support plate Fig 13.

Fig 13

Followed by the pinion gear yoke and pinion gear. Gently push the pinion gear out of the yoke with finger pressure (Remembering which way it goes back – stubby end with the slot faces down) Fig 14.

Fig 14

Now lift the clutch plate off its pin. Fig 15.

Fig 15

Remove Clutch release trigger (push button). Fig 16.

Fig 16

…and the connecting plate Fig 17.

Fig 17

Clean all parts thoroughly to remove old grease, any debris, grit and other nasties. Now time to re-assemble; re-grease all the parts, remembering to grease the pinion yoke and pinion gear. Firstly, slip the connecting plate onto its pin. Fig 18

Fig 18

…followed by the trigger (push button). Fig 19

Fig 19

…and clutch plate. Fig 20

Fig 20

Slip the pinion yoke and gear back on to the two posts. Fig 21

Fig 21

The support plate is next to go on making sure that the spring loaded pin on the left hand side engages with the lobe on the end of the clutch plate. Figs 22 & 23

Fig 22

Fig 23

Turning our attention to the drive shaft and drag system, start by replacing the small spring washer onto the spindle, followed by the drive shaft and the attached release gear. Fig 24

Fig 24

Now rebuild the remained of the system in the following order: Drive washer, drive gear, fibre drag washer, key washer (flat), fibre drag washer, ear washer, fibre drag washer, key washer (domed), one way bearing. Figs: 25, 26, 27, 28, 29, 30, 31, 32 & 33

Fig 25

Fig 26

Fig 27

Fig 28

Fig 29

Fig 30

Fig 31

Fig 32

Fig 33

Replace the right hand side plate and secure to the brake plate with the two screws. Fig 34

Fig 34

Pop the cast control bush back into its aperture – bevelled end goes in first, leaving the flat end showing. Fig 35

Fig 35

Put all this to one side now, while attention is turned to the other side (left).

Undo the three side plate screws and put in a safe place (these are not captive screws and will escape at the slightest chance). Remove the left side plate. Figs 36 & 37

Fig 36

Fig 37

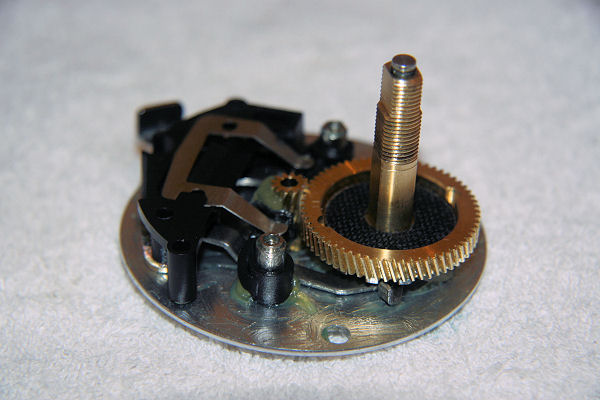

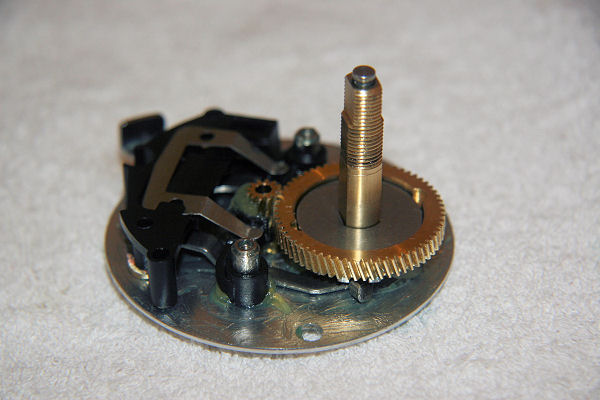

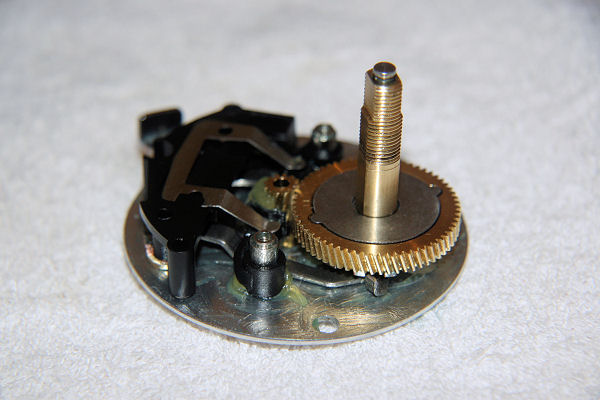

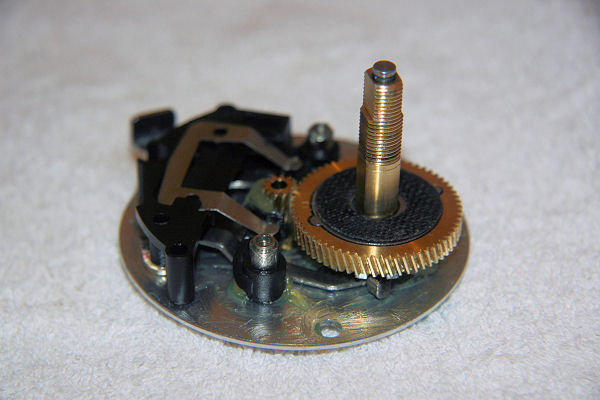

From inside, looking at the magnetic seat (magnet carrier), there is a screw in the centre, which when unscrewed, will release the small knurled magnet adjuster from the carrier and both parts can be removed from the side plate. There is no real need to take things apart any further here unless there are damaged items that need replacing. A general clean out of any debris, grit and old grease will suffice. Before re-assembly, apply a smear of new grease to moving parts and a drop of oil to the spindle of the large white Oscillation cog wheel. Fig 38

Fig 38

Undo the larger knurled cast control cap and pop out the bushing underneath. A general clean and a drop of oil in the bushing before popping it back in (pointy end goes in the cap) is about all that’s needed here. Fig 39

Fig 39

Now for the level wind system. Looking at the end of the cage, release the the thin, curved lock plate by sliding from under the small brass cog. Figs 40 & 41

Fig 40

Fig 41

Then turning the reel over, unscrew the level wind nut and pop out the pawl underneath it. Figs 42 & 43

Fig 42

Fig 43

Taking hold of the small brass cog on the end of the cage, carefully withdraw the worm shaft and the line guide, followed by the level wind itself. Fig2s 44 & 45

Fig 44

Fig 45

Give all parts a thorough clean to remove the usual, grease, crud and grit. Crap does find its way into the line guide, so I tend to clean it our using one of those ‘Q’ tip type things – which, by the way, I reckon were designed specifically for the job, long before they were hijacked for cleaning gunk out of ears and other orrifices. Fig 46

Fig 46

Now that everything is off the cage, it gives a great opportunity to give it a thorough clean, using a fine toothbrush if necessary, to get in all the nooks and crannies. Once everything is clean and shiny, it’s time re-assemble in the reverse order as follows: Fig 47, 48, 49, 50 & 51

Fig 47

Fig 48

Fig 49

Fig 50

Fig 51

Fig 52

Now all that’s left is to put the side plate back on, check that the screws are secure Fig 53

Fig 53

Turning to the spool (if you’ll pardon the pun), normally it only requires a quick clean and drop of oil on the bearings but if the spool seems to be making a weird noises that sound like a coffee grinder, you might want to pop the bearings out for a proper clean, so…. Pull the white plastic line alarm cog wheel off the left side of the spool and gently prise out the bearing from under it. Figs 54 & 55

Fig 54

Fig 55

Then from the other side of the spool, remove the retaining ‘C’ clip ring from under the brake support and then lift off the brake support, before gently prising out the bearing and the washer under it. Fig 56, 57, 58

Fig 56

Fig 57

Fig 58

For a good clean, put the components in a a solvent resistant container and cover in lighter fluid. Agitate all the bits to make sure all old oil and contaminants are removed. Fig 59

Fig 59

Once satisfied that they are clean, remove from the fluid and put on absorbent paper towel or similar and leave to air dry in a dust free space. Once done, re-assemble in reverse order of above. The white cog on the left hand end has two lugs that fit into two spaces on the spool – make sure they engage so that the cog is secure and fits snugly.

Now just to sound one of those lame disclaimers you hear on during or before some TV programmes: (in a stern voice) Please remember to dispose of the lighter fluid in a responsible manner.

Lightly oil the spool shaft and push through the spool. Insert spool through the right hand side of the cage and locate the end of the shaft into the bushing in the left hand side. Fig 60

Fig 60

Pop the brakes onto their pins Fig 61

Fig 61

Put the right hand side plate assembly back onto the cage, ensuring that the four posts correspond to the correct holes. Once back on, do up the knurled captive screws finger tight, before and replacing the right side cast control cap. Fig 62

Fig 62

Put the two spring washers back onto the drive shaft and lightly tap them down so that they’re seated well. Fig 63

Fig 63

Now put back the last of the components onto the drive shaft in the following order: Star drag adjuster, handle spacer, handle, handle nut, handle nut retaining plat and finally, the handle nut retainer screw. Figs, 64, 65, 66, 67, 68, 69

Fig 64

Fig 65

Fig 66

Fig 67

Fig 68

And that’s it, all done. To make sure all is working ok with no problems, check that the spool disengages cleanly and re-engages when the spool is turned by the handle. Check that the drag system works smoothly with no snatchiness. Make sure that the spool spins smoothly with no excessive noise. Ensure that the level wind works correctly. In general, does the reel run like new? If any problems are encountered, strip it down again and find the source of the problem, don’t leave it until you’re on the beach with the fish of a lifetime on the other end – because you can bet a pound to a pinch of crap that that’s when the reel will fail.

For all reel schematics and part numbers, take a look here

[stextbox id=”grey” caption=”Parts List” color=”000066″ bcolor=”000000″ bgcolor=”e3e1dd”]

Handle nut retainer screw: Part no. 8907

Handle nut retainer: Part no. HD-6505

Handle nut: Part no. 66119

E-clip: Part no. 8846

Handle assembly: Part no. 66509

Handleknob cap: Part no. 37192

Handle spacer: Part no. 7058

Star drag adjuster: Part no. 66507, 66508, 22631-3

Right side plate assembly: Part nos. 66116, 66101-1, 66102, 6992, L7099, 5326

One way bearing (Instant Anti Reverse): Part no. (not sure – diagram very confusing)

Right cast control cap: Part no. 7604-1

Right cast control bushing: Part no. 66137

‘O’ ring: Part no. 5229-1

Sideplate screws (x2): Part no. 246

Sideplate screw washers (x2): Part no. L7100

Brake plate assembly: Part no. 66130, 66121, 66127, 66128, 66131

Spring plate: Part no. 66126

Support plate: Part nos. 66125, 66132, 66133

Pinion gear yoke: Part no. 66124

Pinion gear: Part no. 66107

Clutch plate: Part no. 66123

Release trigger: Part no. 66135

(connector) Plate: Part no. 66122, 66129

Spring washers (x2): Part no. 66115

Key washer – stainless steel (domed) : Part nos. 66114

Drag washer – fibre (x2): Part no. 66111

Ear washer – stainless steel (eared): Part no. 66112

Key washer – stainless steel (flat): Part no. 66113

Drag washer – fibre: Part no. 66118

Drive gear: Part no. 66109

Drive washer: Part no. 66110

Release gear gear: Part no. 66106

Drive shaft spring washer: Part no. 66108

Drive shaft: Part no. 66105

Shaft retaining clip plate: Part no. 66139

Spool shaft: Part no. 66402, 66407

Spool: Part no. 66401

Spool ball bearings (x2): Part no. 4*10*4(P5)

Bearing washer: Part no. 66404

Centrifugal brake (x2): Part no. 66406

Centrifugal brake support: Part no. 66403

C-Clip: Part no. KAM-9049-1

Sideplate screws (x3): Part no. 199

Left hand side plate: Part no. 66301-2, 66302, 81705-1, 7057, 4491

Left cast control cap: Part no. 7602-1

base washers (x4): Part no. 5145

‘O’ ring: Part no. 5229

Bushing: Part no. 66303

Magnetic seat: Part no. 66314

Magnet switch: Part no. 66313

Washer: Part no. 66316

Lifter: Part no. 66312

Screw: Part no. 246

Magnetic assembly: Part no. 66311, HD-6311

Click: Part no. 66315

Pin: Part no. 66317

Spring (x2): Part no.HD-6309

Screw (x2): Part no. 1-48

Line guide: Part no. 66210

Level wind assembly: Part no. 66213, 22002

Oscillation cog wheel: Part no. 66304

E-clip (x2): Part no. 8846

Level wind Pawl: Part no. 5176

Level wind nut: Part no. 5177

Worm shaft assembly: Part no. 66212, 5170, 66214

Lock plate: Part no. 5178

Line alarm cog wheel: Part no.66405

Click switch: Part no. 8744-1

Click switch washer: Part no. 8904

Click pawl: Part no. 8745

Click pawl spring: Part no. 4464

Click retainer: Part no. 4467

Click E-clip: Part no. 3909

Click spring: Part no. 24390

[/stextbox]